Vaccine production

Vaccine production应用简介

Comminution of vaccine adjuvants: Aluminum adjuvants (such as aluminum hydroxide and aluminum phosphate) are commonly used adjuvants in vaccines. They need to be made into micron-sized or even nano-sized particles to enhance immune responses. Jet mills can comminute aluminum salt raw materials into uniform fine particles (usually 1-10μm), ensuring the dispersibility of adjuvants, thereby better adsorbing antigens and improving the immune effect of vaccines.

Refinement of poorly soluble excipients: For certain poorly soluble vaccine excipients (such as lipids and polymer carriers), jet milling can reduce their particle size, increase the specific surface area, and improve the uniformity of mixing or dispersibility with antigens in subsequent processes.

Processing of viral or bacterial antigens:

For viruses that need to be lysed or inactivated (such as influenza viruses and hepatitis B viruses), the high-pressure shearing effect of microfluidic homogenizers can gently break virus particles, release internal antigens (such as proteins), while avoiding damage to the antigen structure and ensuring immunogenicity.

For bacterial vaccines (such as pertussis vaccines), homogenization can destroy bacterial cell walls, extract effective antigen components, and achieve homogenization of antigen solutions.

Emulsification and nanonization of vaccine adjuvants:

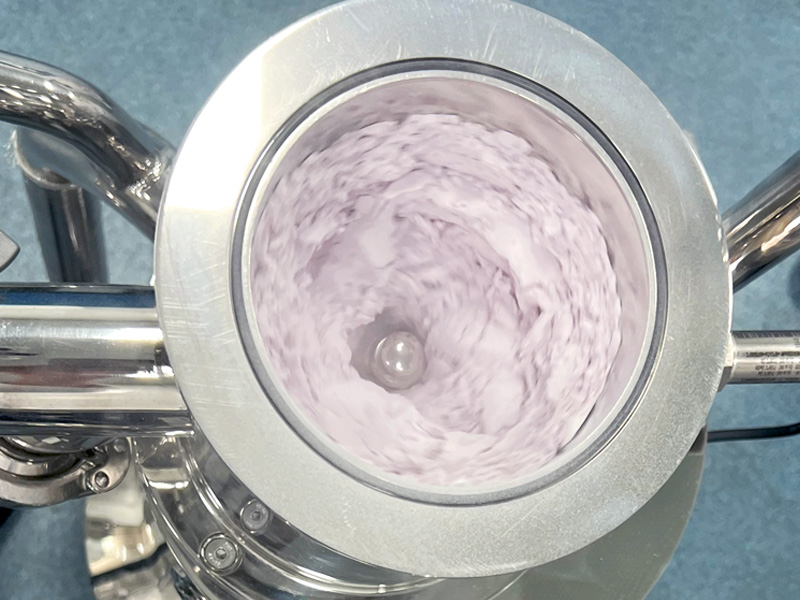

For water-in-oil (W/O) or oil-in-water (O/W) adjuvants (such as oil emulsion adjuvants like MF59 and AS03), microfluidic homogenizers can mix and emulsify the oil phase and water phase at high speed to form nano-sized emulsion droplets with uniform particle size (usually 50-500nm), enhancing the interaction between adjuvants and antigens and improving the immune effect.

For liposomal vaccines (such as lipid nanoparticles (LNP) carriers in mRNA vaccines), high-pressure homogenization can promote the ordered assembly of lipid molecules, form stable nano-liposomes, encapsulate nucleic acid antigens such as mRNA, protect them from degradation, and promote cellular uptake.

Homogenization and stabilization of vaccine suspensions:

Vaccine finished products are often suspensions (such as vaccines containing aluminum adjuvants). Microfluidic homogenization can break particle agglomeration, make the adjuvant-antigen complexes more uniformly dispersed, avoid precipitation, and extend the shelf life.